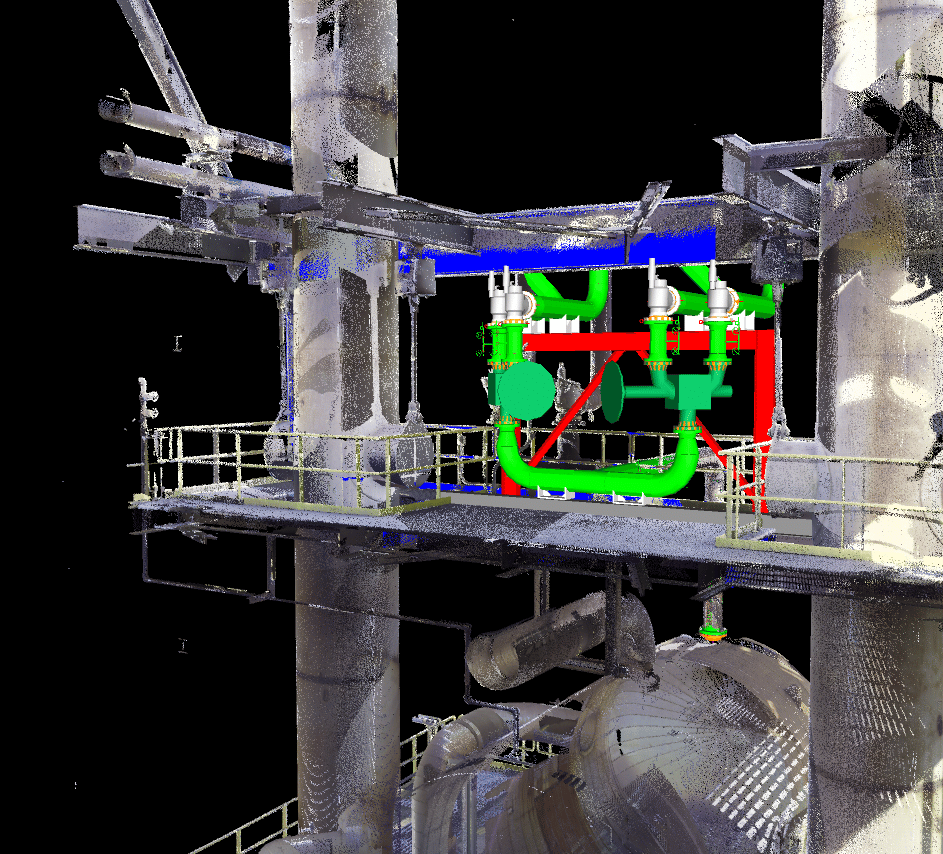

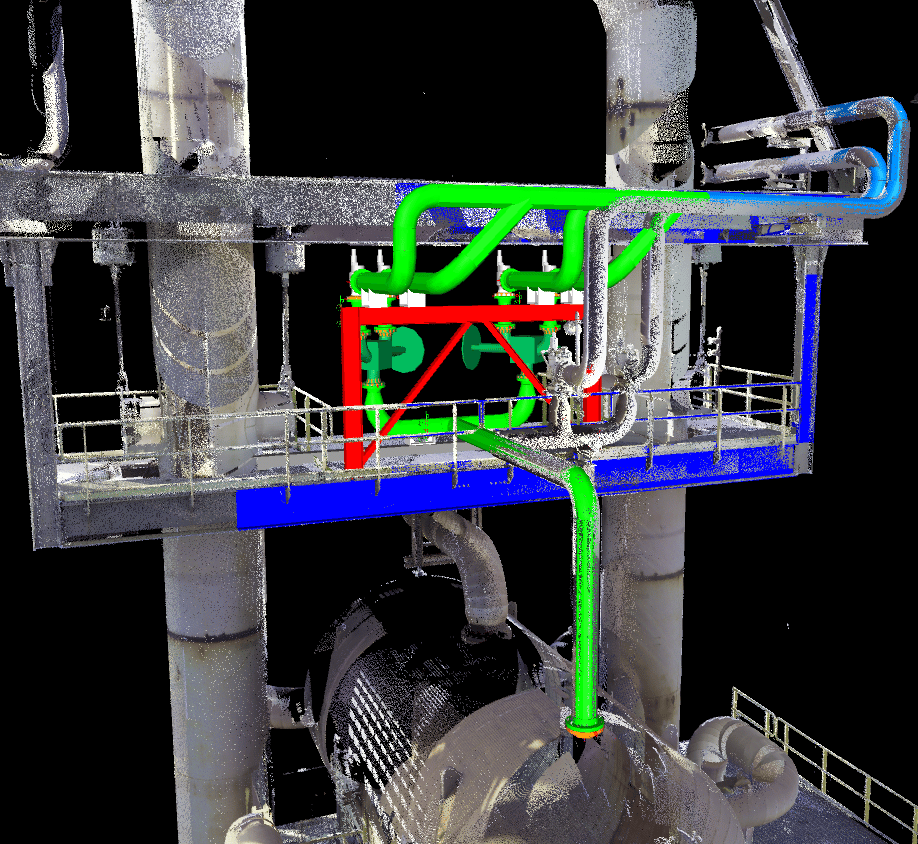

Convent Steam Drum

The customer wanted to install crossover valves on their steam drum piping to keep their steam drum in production. The work occurred at high elevation, so field measurements would have been a challenge. We decided to move forward with a 3-D laser scan of their reactor tower so we could redesign the piping system. The piping system and supports were custom-built for the customer, and model reviews were held to ensure that the customer got exactly what they wanted. The model was accurately built according to the laser scans, and all the pipe spools and supports were prefabricated for quick installation with minimal downtime.