Pressure Vessel Replacement: Design, Fabrication, and Install

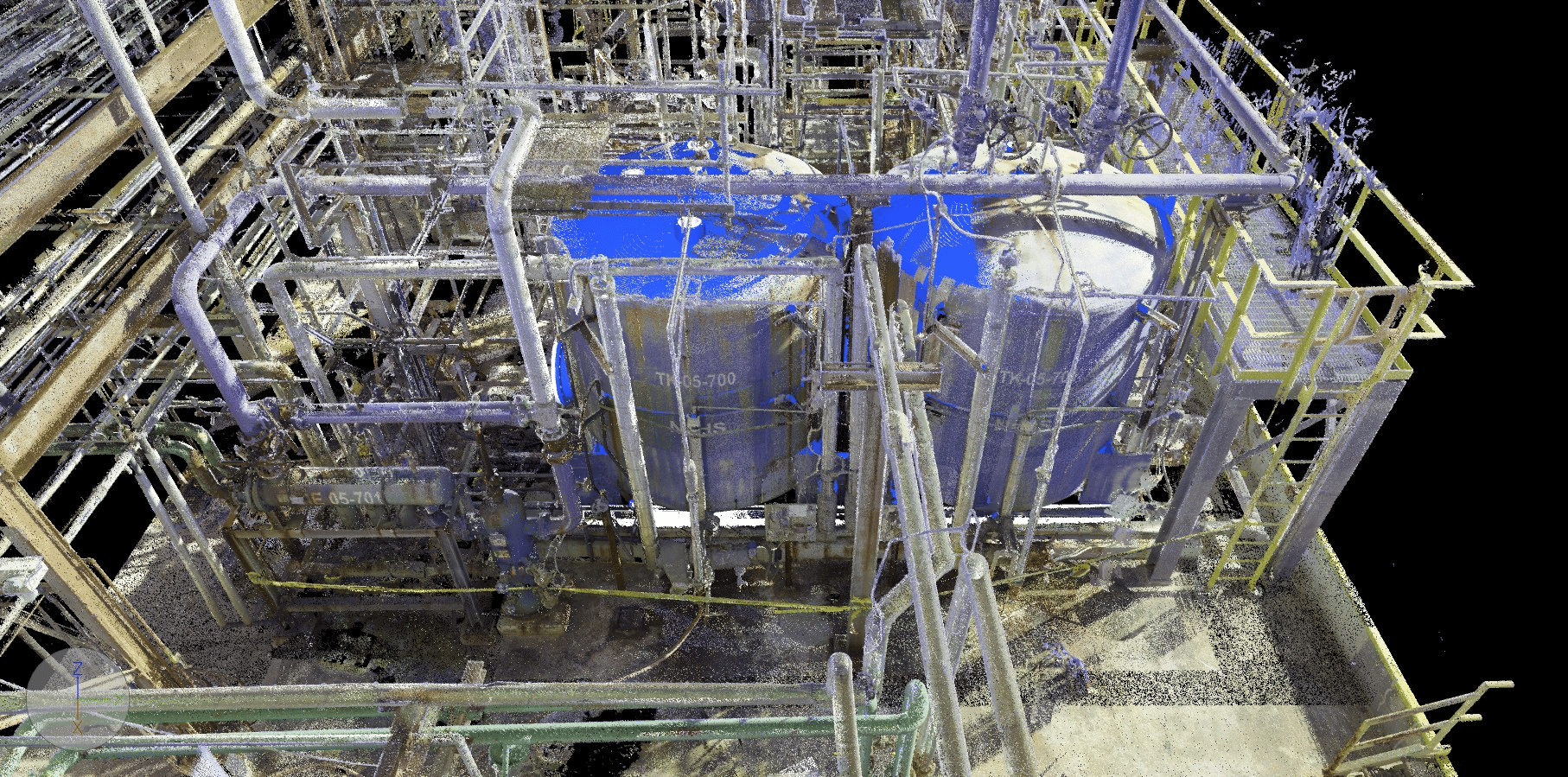

For this job, the customer had two identical pressure vessels, but only one was in operating condition. They requested that we generate fabrication drawings of an identical pressure vessel, for a replacement. We started by scanning both tanks as they sat. From that scan we were able to get the overall dimensions the tank needed to be, along with any support frame. Our engineering team then ran the required calculations for each nozzle to get the appropriate stud flange dimensions. The customer then requested we add additional nozzles. A 3D model and fabrication drawings were generated and turned over to the customer.

Due to time constraints, the customer proposed using an existing pressure vessel they had on site that was no longer used, but still in operating condition. This pressure vessel was very different in size so they wanted us to find out what it would take to use it. We scanned the new tank and were able to generate a 3D model from it. We then overlaid the new pressure vessel scan and model in the spot of the one being replaced so the customer could identify any foundation work/alterations to the vessel/reroute or demo work that needed to be done.

Pictures of the original design can be found below, along with the option for the second, much larger tank.