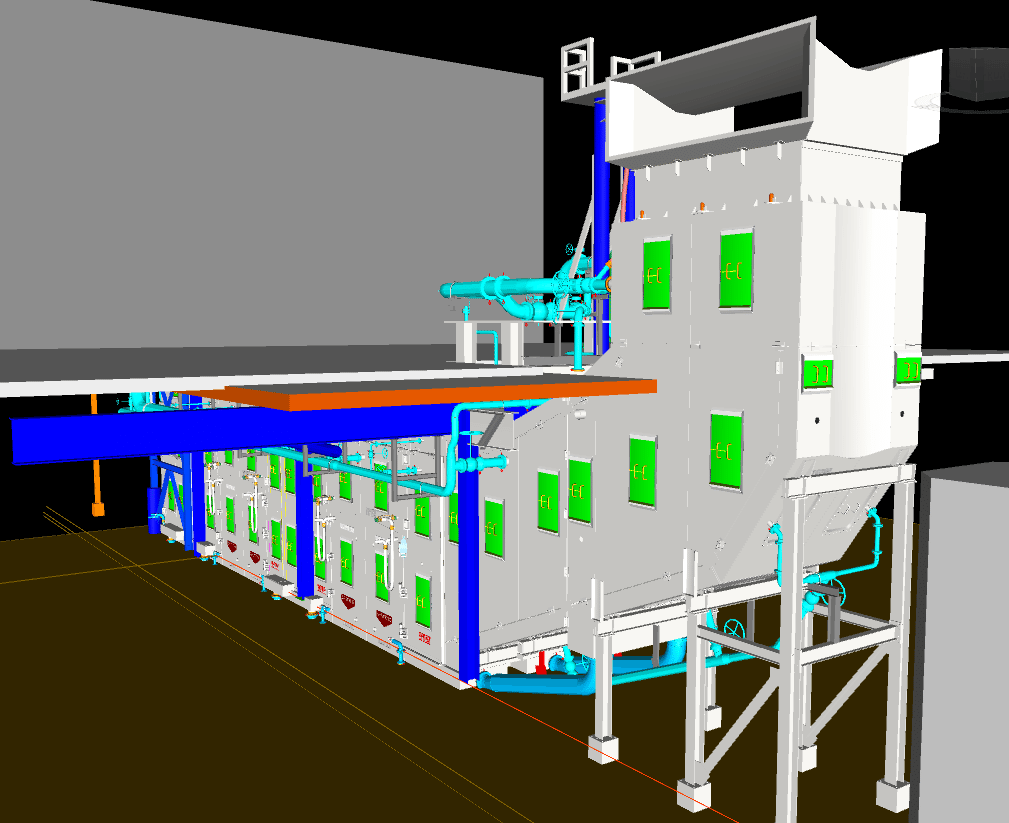

Spray-Cooled Drop-Out Chamber Piping Engineering & Fabrication

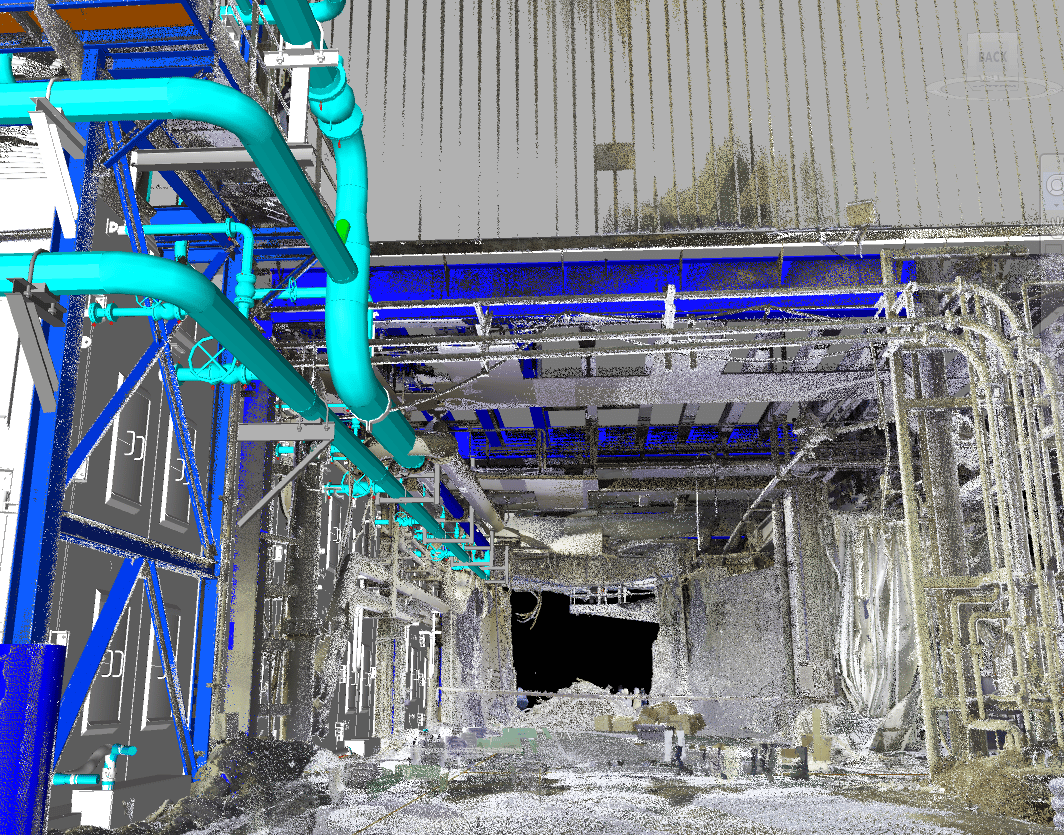

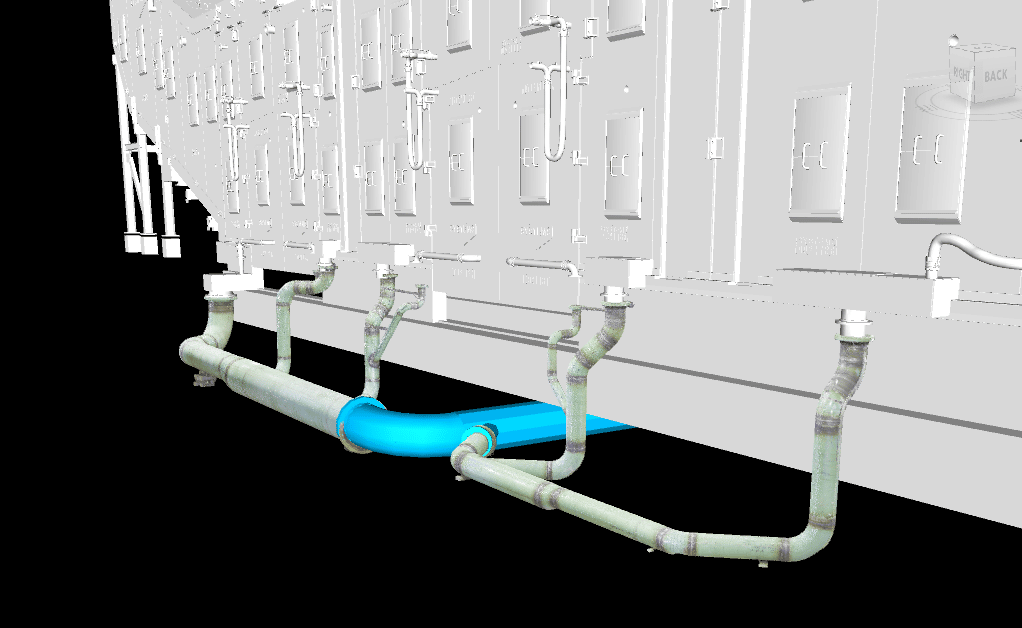

The customer decided to install a new Systems Spray-Cooled Panelized Drop-Out Chamber for their melt shop. Space was tight and the plant had very short windows to install the pipe. To keep the plant running, the engineering and fabrication of piping had to be perfect. The underground gravity return lines were sloped and required many miters and odd-ball angles. The pipe was modeled, spool drawings were made, and the pipe was carefully fabricated in our shop. As an extra check, we laser-scanned the underground pipe spools after they were fabricated and inserted them into the model – it was a perfect fit. Now, we can install these underground pipes with confidence, pre-assembled, and ready to install within a 24-hour down day. That’s right. 24 hours.

The remainder of the pipe and supports were engineered in the same fashion – modeled according to the equipment drawings and laser scans to ensure an accurate fit-up with minimal downtime. Problems are worked out in the engineering phase, reducing the amount of costly field rework and schedule delays. A large majority of the welds were made in our state-of-the-art fabrication facility, reducing the time it takes to make the welds, and significantly reducing the amount of welds that must be made in the field while the plant is down. Systems gladly assisted with the pipe specifications, valve specifications, as well as, instrumentation. Interferences were not an issue, because Systems was able to model and fabricate down to a 1/16” tolerance.